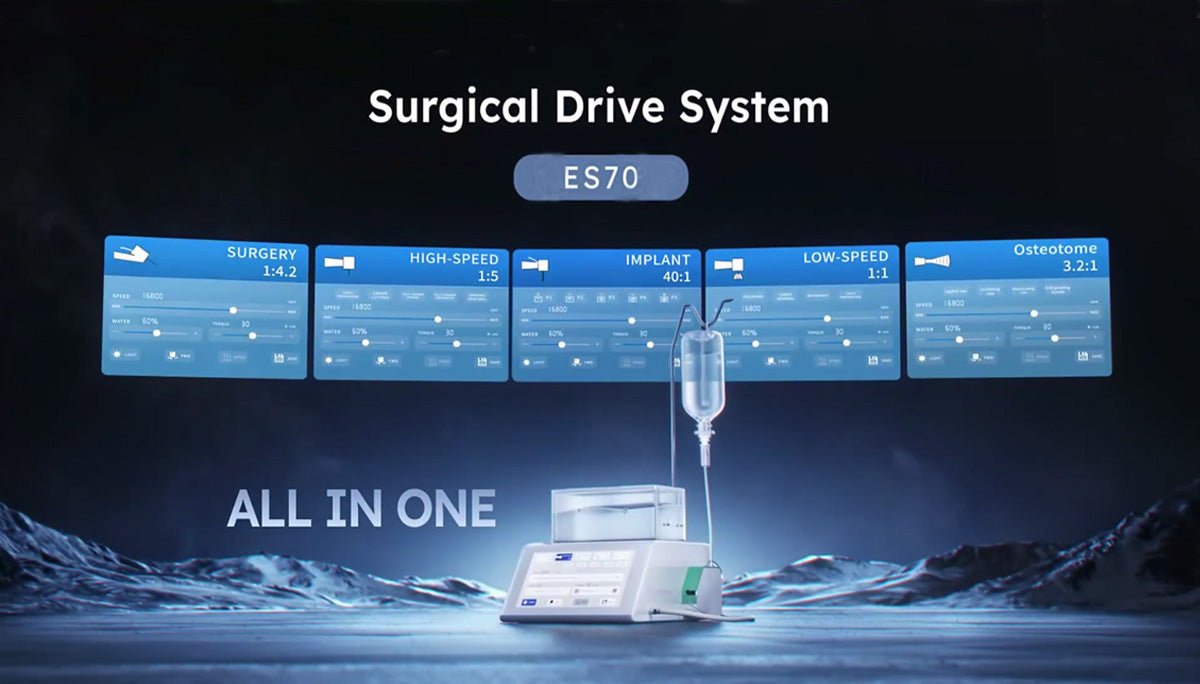

The Jinme ES70 Surgical Drive System is engineered with industrial-grade chips for immediate responsiveness, empowering you with unmatched precision and control. It is a comprehensive dental device designed to streamline the diverse needs of dental professionals. Designed to be an extension of your skill, this system adapts instantly to your touch, delivering flawless performance across a variety of clinical applications. Every function is created with the clinician in mind, allowing you to meet each patient’s needs confidently and efficiently. it is an ideal choice for various dental procedures such as extractions, restorations, polishing, caries removal, and implants.

Key Features

Water tank for easy use

Simple and clear operating interface very easy to control

Use ultra quiet peristaltic pump for continuous silent output

Compact Design: Main unit dimensions of 260mm x 240mm x 110mm, perfect for seamless integration into any dental workspace.

Free Four Compatible Handpiece:

Electric Surgical High-Speed Handpiece (1:4.2)

Electric High-Speed Contra-Angle Handpiece (1:5)

Electric Low-Speed Handpiece (1:1)

Electric Implant Handpiece (40:1)

Wide Motor Speed Range: Adjustable motor speeds from 0 to 40,000 RPM to meet the demands of different dental procedures.

High-Quality Motor Rotation Modes: Forward and reverse rotation modes for enhanced control during procedures.

Efficient Power Consumption: Maximum power usage of 180VA, with a rated motor voltage of DC32V for consistent performance.

How to Use

1) The power switch "I/O"(on the back of this device) is used to turn the host on and off. This device can be shut down immediately regardless of any operation at any time.

2) After the power wire is plugged in, and the power supply is turned on, the display screen of the host will be on.

*Motor stalling torque is 2.5N.cm. When the motor load is greater than it, the motor will automatically stop working.

*When 40:1 handpiece (W401LW) and tapping program are selected, the maximum output torque is 70N·cm(±10%).

3) Speed setting: Drag the speed regulating progress bar left and right on the display screen, to show the rotation speed of the handpiece in numbers on the screen. Drag to the left to reduce the speed and drag to the right to increase the speed. Press "- to reduce the rotation speed and "+ to increase the rotation speed.

When the speed setting value is the upper limit value or the lower limit value of the speed in the current transmission ratio mode, the buzzer will give "Bi-Bi" sound, indicating that the speed has reached the limit value.

4) Flow setting: Drag the flow regulating progress bar left and right on the display screen, to display the flow on the screen in a digital percentage. Drag the left to reduce the flow, and drag the right to increase the flow. The flow regulating range is 0-100%, and the step amount is 10%, which is divided into 11 levels. Press "- to reduce the flow and "+ to increase the flow.

5) Torsion setting: Drag the torsion regulating progress bar left and right on the display screen, to show the maximum allowable in numbers on the screen. Drag to the left to reduce the torsion and drag to the right to increase the torsion. The torsion regulating range varies according to different handpieces. See the torsion range in the table above. Press " to reduce the torsion and "+ to increase the torsion.

6) Motor light regulating

On/off: Click the LED icon to control the brushless direct-current motor to be on/off. 7) Forward and reverse rotation

Clicking the forward/reverse rotation icon will change the direction of operation of the motor.

8) Atomizing water switch (cooperating with the registered and valid pre-sterilized disposable water supply pipe, with a specification of 6mm*4mm for extrusion section)

On/Off: Click the atomization icon to control atomized water to be on/off.

9) Program reading and writing

Reading: Click the read-write setting icon once to enter the recently stored setting program; click again to enter next setting program to save the current interface setting program.

Writing: Press and hold the read-write setting icon for three seconds. When you hear a beep, write the parameters on the current screen. (The upper left corner shows the program memory bit number)

If you would like more information or would like to purchase this product, please click here, or contact our customer service team

Email

service@azdentall.com

Call Us

+86 13203838215